-

-

Lay 4x P22 pieces on top of some scrap/spare 1/4" thick steel (these are used as guides).

-

Tack them onto the tubes.

-

Finish the welds and fill the spaces.

-

-

-

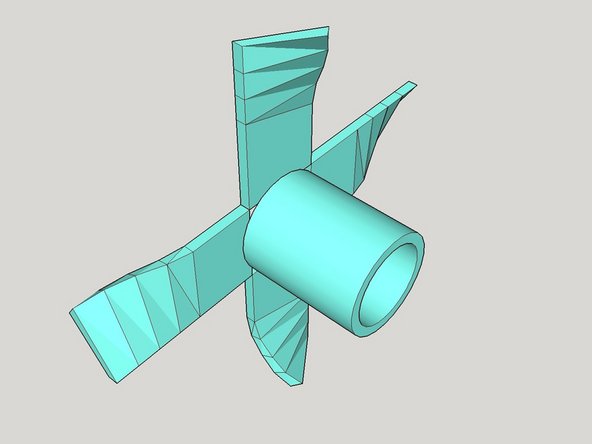

Put the 3" pipe section in a vice, clamping along the length of the tube. Twist each plate about 35 degrees with a large monkey wrench, alternating the direction for each one

-

-

-

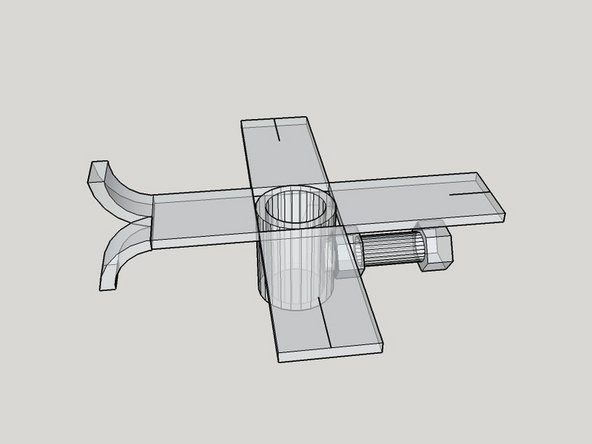

Note here there are two variations in the tine modules. Cut the hole in the side of the pipe for the bolt to pass through with an oxy acetylene torch, ensuring that at least 9 of the 18 tine modules will have a hole offset by 45 degrees to the other 9 modules.

-

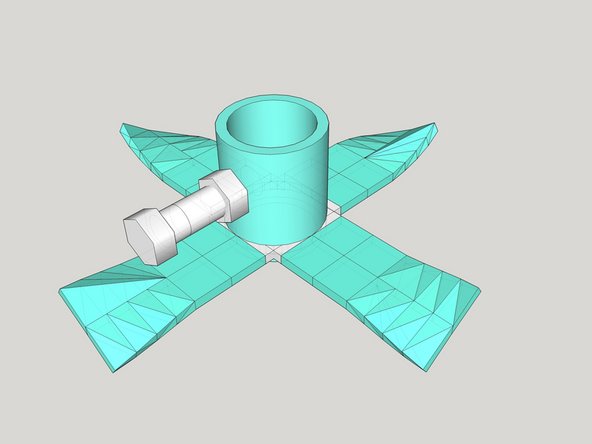

Weld a nut for the 3/4" bolts here.

-

Thread the bolt through. This completes the build one tine module. After creating one or 2 many can be made at once.

-

-

-

Bend the tips of the tines with a monkey wrench by hand to produce the curved tips (about 30 degrees). if possible bend keeping the leading edge straight. you will need half the blades bent one way, and half the other way. Each complete tine module is the same.

-

Repeat for all 9 tine modules of one type, then the other 9. Process cutting and welding of some parts in batches where suitable. We recommend going through the process of 1 module first, before doing batches.

-