Introduction

We are going to break down the framing into 11 framing modules that will be assembled on the ground in parallel with other construction processes.

This is the how-to for the modules of the 2nd floor. Starting from the south, they are labeled 4-9 with an "a" and "b" distinction referencing their location on either west or east respectively.

-

-

Gather materials for mod 9a&b (these are enough materials for BOTH walls)

-

8:2x4x8

-

2:2x4x10

-

2 sheets of 3/4"x4'x8' OSB for exterior sheathing

-

2 sheets of 1/2"x4'x8' plywood for interior sheathing

-

~buncha 3-1/8" construction screws

-

~buncha 1-5/8" coated deck screws

-

-

-

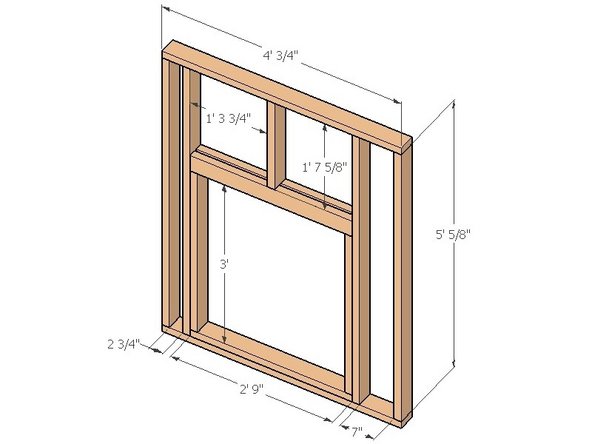

Cut Framing Members

-

4: 2"x4"x5'5/8" (verticals)

-

2: 2"x4"x4'3/4" (horizontal top/bottom)

-

3: 2"x4"x2'9" (window frame top/bottom)

-

2: 2"x4"x3' (window frame sides)

-

1: 2"x4"x1'7-5/8" (blocking over window)

-

1: 2'8"x3.5"x1/2" plywood

-

-

-

Assemble Framing

-

Place vertical studs (60-5/8") inside horizontal top and bottom plates (48-3/4")

-

Sandwich plywood strip between two of the three 33" pieces and screw together (three screws across length is fine)

-

Use sandwich to form top of window box, use 3' members to form sides and remaining 2'9" member for the base; screw together with 3-1/8" screws (toe-in screws at a diagonal into top plate from side members)

-

Screw one stud (60-5/8") to either side of window box; letting top of studs hang free off the top of the window box but making sure they are all aligned at the bottom

-

Toe-in center vertical above window box

-

Place top and bottom plate such that vertical studs at edges leave a gap of 7" to one side of window, and 2-3/4" on the other.

-

-

-

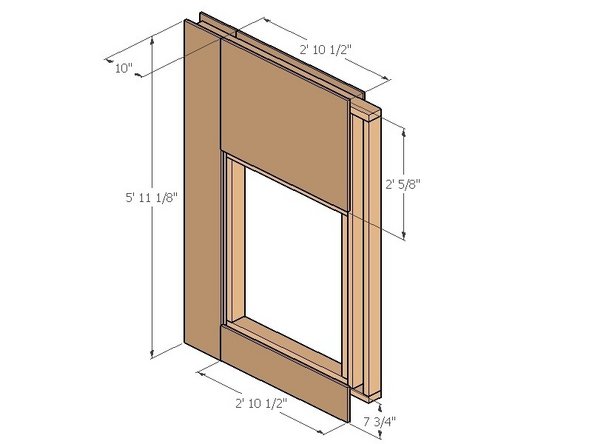

Cut and attach Exterior Sheathing (OSB)

-

1: 34-1/2"x24-5/8"x3/4" OSB

-

1: 34-1/2"x7-3/4"x3/4" OSB

-

1: 71-1/8"x10"x3/4" OSB

-