-

-

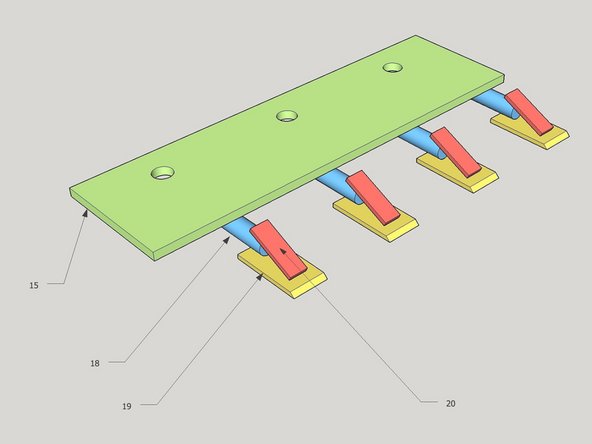

Take P18

-

Lay P19 flat

-

Weld P18 with 1" overlap onto center of P19

-

-

-

Weld P20 to make 1/2" of P19 (cutting knife) exposed at the cutting edge

-

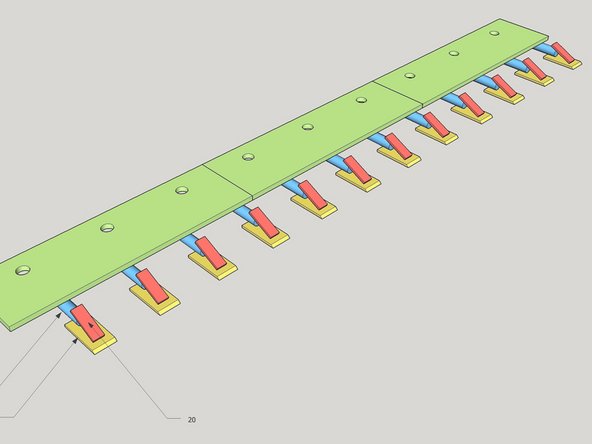

Repeat for the total 12 teeth

-

-

-

Weld 4 teeth at the proper spacing (4" on center ? and 2" on center from edge ? ) to part 15 (tooth bar bolt bar), with X inches overlap between P18 and P15

-

Repeat for the 2 other P15 parts

-

-

-

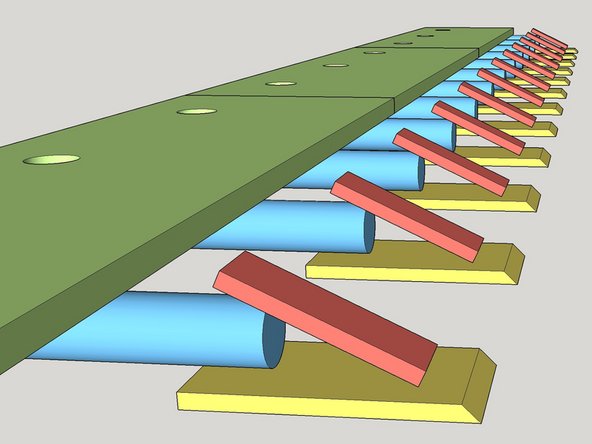

Grind teeth at 45 degree angle with tooth bar weldment in a vice

-

Water harden or air harden the teeth by heating to red hot with acetylene torch and then dunking in water

-

-

-

Quality control Checklist

-

Make sure that P18 and P19 overlap by 1"

-

Make sure that P18 and P19 are centered with respect to one another

-

Make sure that 1/2" of cutting knife is exposed, and that 1/4" is exposed after grinding

-

Make sure that P15 is oriented with the holes pointing away from the teeth

-

Make sure that the angle between P15 and P18 is 90 degrees

-