Parts

- Extruder Body

- Extruder Idler with 608 bearing installed

- Extruder Washer

- Large Herringbone Gear with Hobbed Bolt

- Small Herringbone Gear

- Extruder Latch

- Extruder Spring

- Motor - 2

- 608 Bearing

- M3 x 6mm Set Screw

- M3 x 12 SHCS

- M3 x 25 SHCS

- M3 Nut, Zinc

- M3 Washer

- M4 x 55 SHCS with Thumb Screw Knob

- M4 Nut, Zinc

- M4 Washer

- M8 Nylon Nut

- M8 Washer

- M8 Shim Washer 0.5

- M8 Shim Washer 1.0

-

-

Gather parts and tools for Extruder Assembly

-

Photo 1 - 1.5mm Allen Driver

-

Photo 2 - 2.5mm Allen Driver

-

Photo 3 - 13mm Wrench

-

-

-

INSTALL IDLER BOLT

-

Install M3 x 25 SHCS, M3 Washer and M3 Nut into the Idler assembly

-

Only put the screw in until the tip is flush with the nut

-

TIP: Set M3 Nut into the hexagon cutout and hold with your finer to install the bolt

-

-

-

INSTALL EXTRUDER WASHER INTO BODY

-

Place the printer extruder washer into the extruder body

-

-

-

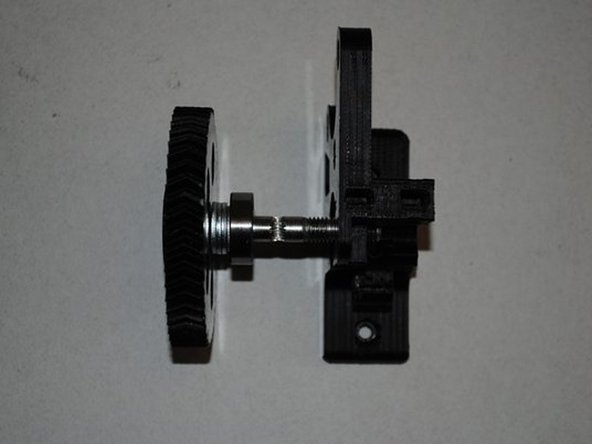

INSTALL GEAR, BOLT AND FIRST BEARING

-

Install 4 x M8 washers onto the hobbed bolt then a 608 bearing.

-

Once installed, does the hobbing on the bolt line up with the small hole going through the extruder body?

-

If you need to adjust it's location, you can add either a 0.50mm or 1.0mm shim washer to get the correct spacing.

-

Does the hobbing line up with the hole in the center?

-

-

-

INSTALL SECOND BEARING

-

On the opposite side of the gear, add a 608 bearing, M8 Washer and a M8 locknut.

-

Tighten the Locknut down until the bearing is seated and there is no space between the Nut, Washer and Bearing.

-

The large gear shouldn't be able to rock back and fourth but should spin freely.

-

Does the gear turn freely?

-

Does the hobbing still line up with the hole in the body?

-

Record what type and how many washers were used.

-

-

-

INSTALL IDLER ONTO BODY

-

Install extruder idler onto the body.

-

Tighten the M3 x 25, SHCS bolt down to secure the Idler

-

Tip: Place the leg with the nut on the body first and twist the Idler onto the body.

-

Does the Idler swing freely on the bolt?

-

-

-

SMALL GEAR ASSEMBLY

-

Install the M3 nut into the bottom of the small herringbone gear.

-

Then install the M3 x 6mm set screw through the side of the small gear and into the nut.

-

Be sure the M3 x 6mm set screw does not protrude into the hole through the small gear.

-

-

-

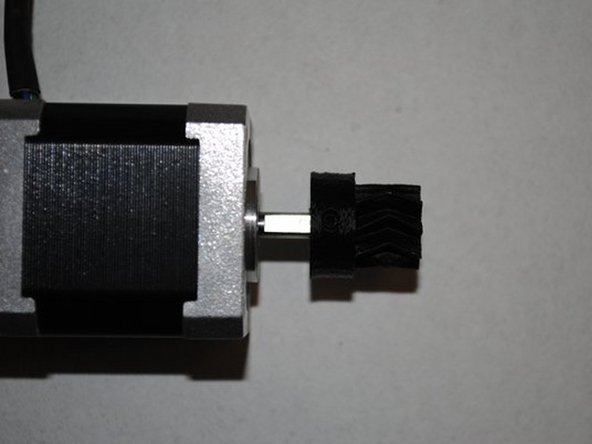

INSTALL GEAR ON MOTOR

-

Locate the flat side of the motor shaft.

-

With the set screw aligned with the flat, slide the small gear onto the motor shaft.

-

The location will be adjusted later so positioning isn't important at this point.

-

Do not tighten the set screw yet.

-

Is the set screw aligned with the flat?

-

-

-

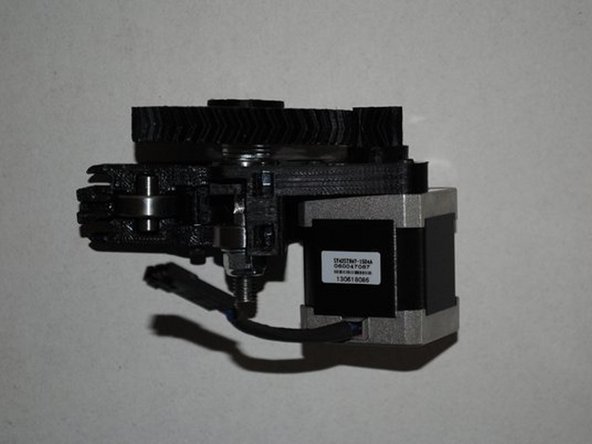

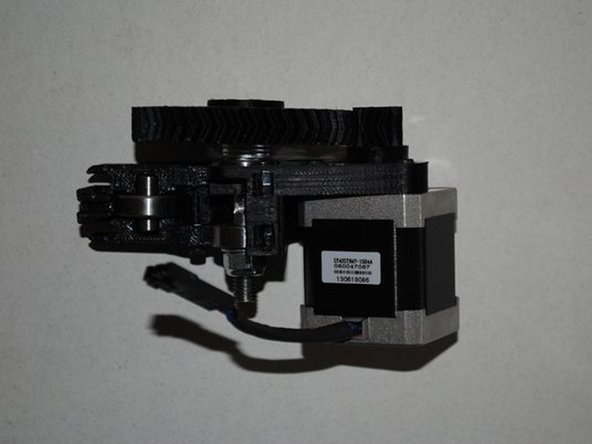

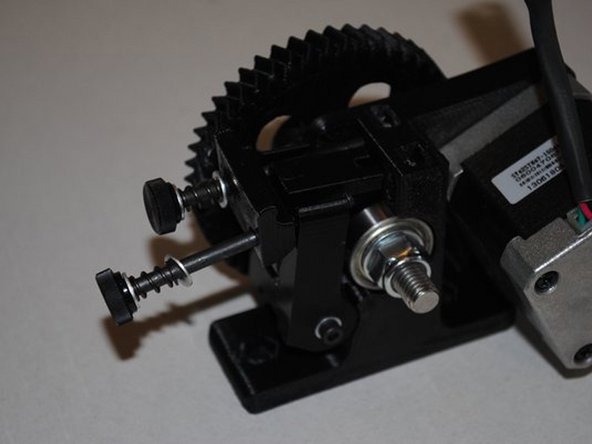

INSTALL MOTOR

-

Holding the motor in the location where it will be mounted, align the herringbone gears by sliding the small gear in or out on the motor shaft so the V-grooves are centered on each other.

-

Install motor using 3x M3 x 12mm SHCS and 3x M3 washers, taking note of the orientation of the motor wires.

-

Push the gears together while you tighten the bolts to make sure the contact is tight.

-

Tighten the set screw on the small herring bone gear.

-

Are the motor wires oriented correctly?

-

Are the V-grooves of the gears aligned?

-

Is there any back-lash in the gears? Can you spin the large gear for several rotations?

-

-

-

INSTALL M4 NUTS INTO TOP OF BODY

-

Install 2x M4 nuts into the top of the extruder body as shown.

-

Make sure you can see the nuts from the side so you can install bolts later.

-

Tip: Nuts only go in one way, the flats of the nut must be vertical.

-

Photo 1 - Nuts in body from top

-

Photo 2 - Nuts in body from side

-

-

-

INSTALL IDLER TENSIONER

-

Install M4 x 55 with thumb knob, M4 washer, extruder spring, M4 washer and Extruder latch into M4 nut installed in body.

-

Then put another M4 x 55 with thumb knob, M4 washer, extruder spring, M4 washer through the Extruder latch and into the body.

-

Photo 1 - Prep parts for assemby

-

Photo 2 - Idler tensioner assembly

-

Can you adjust both bolts in and out by hand?

-

Can you swing the tensioner up and down?

-

-

-

REVIEW THE EXTRUDER ASSEMBLY

-