Introduction

Before you start this guide, you should have followed all the other ironworker guides to build the different modules.

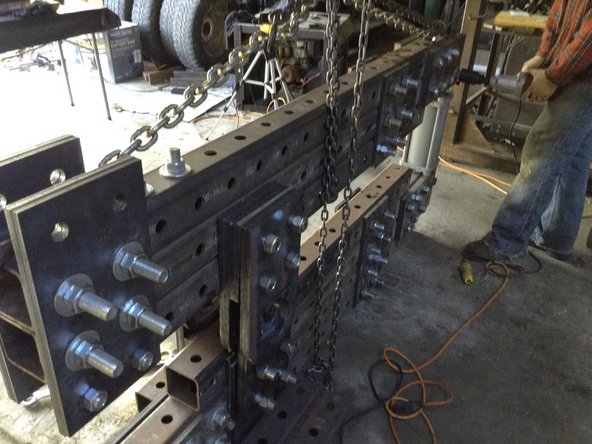

This guide will walk you through putting them all together into a complete machine.

-

-

TODO I don't think this video should be in the guide. It more about the process of documenting it and talks about disassembling which may be confusing to people. It doesn't add any info.

-

-

-

Parts:

-

1 10" x 1" hardened bolt

-

1 1" nut

-

4 1" washers (spacers)

-

Put a bolt through a drilled out nut, the bottom hole of the plates on the frame, 2 washers, the piston side of the cylinder, 2 more washers, the other plates, and another drilled out nut. Make sure the hose connectors on the hydraulic cylinder face away from the rest of the ironworker.

-

TODO better 1st pic

-

Put a nut on the bolt but don't tighten all the way.

-

If you have trouble getting the bolt through, try using an impact wrench to drive it through. If that doesn't work, it may help to loosen the plates with the welded nuts. Make sure not to put in too many spacers while they're loose and to tighten them when you're done.

-

-

-

Parts:

-

1 10" x 1" hardened bolt

-

3 1" washers

-

1 1" nut

-

Put a bolt through a drilled out nut, the bottom hole of the plates on the frame, 2 washers, the base side of the cylinder, 1 more washer (on ours there was only room for 3 spacer washers), the other plates, and the last drilled out nut. Make sure the hose connectors on the hydraulic cylinder face away from the rest of the ironworker.

-

Put a nut on the bolt and tighten it and the top one.

-

-

-

Parts:

-

1 oz grease

-

Put grease on the shaft and push it through the pivot plate holes using an impact wrench on the nut welded to the shaft. Each end of the shaft should line up with the outermost pivot plate with a bushing which is the 3rd plate in from each side.

-

If you're having trouble getting it all the way through, here are some things to try:

-

Add or remove weight on the shaft by raising or lowering the hoist.

-

Tighten or loosen the bolts holding the pivot plates.

-

Make sure all the pivot plates are lined up properly.

-

If you still can't get it quite all the way through leave it for now. As long as it's close, you'll be able to pull it the rest of the way through with the pinch plates in a couple of steps.

-

-

-

Parts:

-

2 1" x 2" bolts

-

2 1" washers

-

Take a 2"x1" bolt, put a washer on it, put it through the 8"x8" plate, and screw it loosely into the bolt at the end of the shaft. Then repeat on the other side.

-

If the shaft isn't centered, first put on the plate on the side where the shaft isn't far enough through. Tighten the plate until you see on the other side that the shaft is centered.

-

The point of these bolts and plates is to pinch the pivot joint as tightly together as possible. They should be tightened with about 150 ft-lbs of force.

-

You want the bolt to be most of the way through the shaft nut when fully tightened. If it looks like the bolt will be too long for the nut and will bottom out against the shaft, add more washers. If it looks like the bolt won't get almost all the way through the nut, take out the washer.

-

Remove the wooden supports holding up the 2 cubes in the pivot if they're still there. The pressure from the pivot plates should hold them in place.

-

-

-

Put the lower blade assembly in place so it's hanging off the 6 plates with the blade face up.

-

Adjust the blade assembly and the riser plates so the row of hole closest to the edge of the 2 x 4 hole plate lines up with the holes in the lower frame tube, and the riser plates extend about 1" past the left edge of the blade towards the pivot.

-

-

-

Parts:

-

2 1" nuts

-

1 1" washer

-

1 16.5" x 1" threaded rod (TODO link to guide on cutting threaded rod)

-

Put a piece of plywood or some other spacer on the lower blade and rest the four plates on it.

-

Put a nut and washer on on end of the threaded rod and put it through from the top of the upper frame down through the plates.

-

Put a nut below the plates without a washer. Hand tighten.

-

Remove the wooden support.

-

-

-

Put the table assembly threaded rods through the frame from the side with the lower blade. They should go through the holes on either side of the lower blade plate.

-

TODO from mon- reorg this to have threaded rods in this guide. 17" rods. 5 washers. clamp structure and work surface struture separately. clamp bolts 13"

-

TODO fix bot mid plate everywhere i took pics on mon

-

-

-

Parts:

-

2 12 hole 1/2" tubes

-

3 1" x 16" threaded rod

-

6 1" washers

-

6 1" nuts

-

Put the two upright on either side of the frame near the cylinder as shown.

-

Put threaded rods through the bottom hole, 4th from the bottom hole, and top hole of the uprights. Do NOT put any through the top part of the frame since it needs to be able to move up and down.

-

The uprights make sure the bottom and top stay in perfect alignment so the nuts have to be very tight. Use a hydraulic system to open the ironworker all the way and then use 150 ft-lbs of force when tightening these 3 bolts.

-

-

-

Adjusted the table so that both surface of the table is at the same height as the edge of the blade.

-

To do this, raise the table with the floor jack after loosening table-holding bolts and raise the table level to match the blade edge level.

-

Once the table level is set than retighten the table-holding bolts.

-